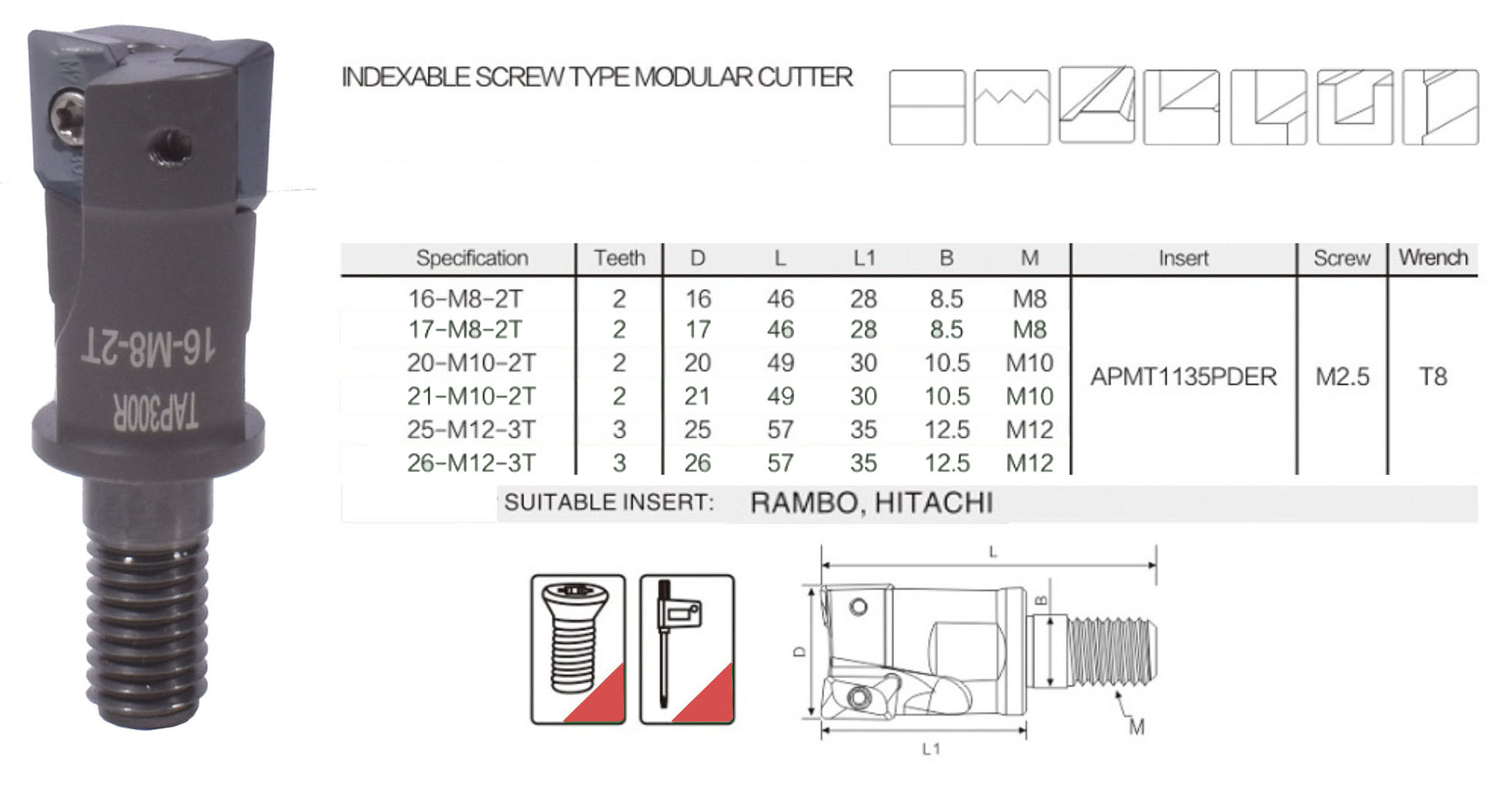

New 300R M10 MODULAR INSERT CUTTER 20MM +2PC APMT1135 CARBIDE INSERTS

| MODEL | TAP300R16-M10-2T | RUN OUT (TIR) | 0.0002″ |

| HOLDER TYPE | FACE MILL CUTTING | DIAMETER | 20MM |

| SHANK TYPE | M10 | INSERT ACCEPT | APMT1135 |

BT30/BT40/CAT40 arbor available

| MODEL | THREAD | D | DC | L | ORDER NO |

|---|---|---|---|---|---|

| BT30 M6 50L | M6 | 12 | 17 | 50 | IGST30001 |

| BT30 M6 100L | M6 | 12 | 17 | 100 | IGST30002 |

| BT30 M8 45L | M8 | 15 | 17 | 45 | IGST30003 |

| BT30 M8 50L | M8 | 15 | 17 | 50 | IGST30004 |

| BT30 M8 100L | M8 | 15 | 17 | 100 | IGST30005 |

| BT30 M10 45L | M10 | 19 | 21 | 45 | IGST30006 |

| BT30 M10 50L | M10 | 19 | 21 | 50 | IGST30007 |

| BT30 M10 100L | M10 | 19 | 21 | 100 | IGST30008 |

| BT30 M12 60L | M12 | 24 | 25 | 60 | IGST30009 |

| BT30 M12 100L | M12 | 24 | 26 | 100 | IGST30010 |

| BT30 M16 45L | M16 | 30 | 33 | 45 | IGST30011 |

| BT30 M16 60L | M16 | 30 | 33 | 60 | IGST30012 |

| BT30 M16 100L | M16 | 30 | 33 | 100 | IGST30013 |

| BT40 M8 70L | M8 | 15 | 17 | 70 | IGST30014 |

| BT40 M8 100L | M8 | 15 | 17 | 100 | IGST30015 |

| BT40 M8 150L | M8 | 15 | 22 | 150 | IGST30016 |

| BT40 M8 200L | M8 | 15 | 22 | 200 | IGST30017 |

| BT40 M10 70L | M10 | 19 | 20 | 70 | IGST30018 |

| BT40 M10 100L | M10 | 19 | 25 | 100 | IGST30019 |

| BT40 M10 150L | M10 | 19 | 25 | 150 | IGST30020 |

| BT40 M10 200L | M10 | 19 | 31 | 200 | IGST30021 |

| BT40 M12 70L | M12 | 24 | 26 | 70 | IGST30022 |

| BT40 M12 100L | M12 | 24 | 32 | 100 | IGST30023 |

| BT40 M12 150L | M12 | 24 | 37 | 150 | IGST30024 |

| BT40 M12 200L | M12 | 24 | 58 | 200 | IGST30025 |

| BT40 M16 70L | M16 | 30 | 32 | 70 | IGST30026 |

| BT40 M16 100L | M16 | 30 | 36 | 100 | IGST30027 |

| BT40 M16 150L | M16 | 30 | 41 | 150 | IGST30028 |

| BT40 M16 200L | M16 | 30 | 46 | 200 | IGST30029 |

| CAT40 M8 70L | M8 | 15 | 17 | 70 | IGST30030 |

| CAT40 M8 100L | M8 | 15 | 17 | 100 | IGST30031 |

| CAT40 M8 150L | M8 | 15 | 22 | 150 | IGST30032 |

| CAT40 M8 200L | M8 | 15 | 22 | 200 | IGST30033 |

| CAT40 M10 70L | M10 | 19 | 20 | 70 | IGST30034 |

| CAT40 M10 100L | M10 | 19 | 25 | 100 | IGST30035 |

| CAT40 M10 150L | M10 | 19 | 25 | 150 | IGST30036 |

| CAT40 M10 200L | M10 | 19 | 31 | 200 | IGST30037 |

| CAT40 M12 70L | M12 | 24 | 26 | 70 | IGST30038 |

| CAT40 M12 100L | M12 | 24 | 32 | 100 | IGST30039 |

| CAT40 M12 150L | M12 | 24 | 37 | 150 | IGST30040 |

| CAT40 M12 200L | M12 | 24 | 58 | 200 | IGST30041 |

| CAT40 M16 70L | M16 | 30 | 32 | 70 | IGST30042 |

| CAT40 M16 100L | M16 | 30 | 36 | 100 | IGST30043 |

| CAT40 M16 150L | M16 | 30 | 41 | 150 | IGST30044 |

| CAT40 M16 200L | M16 | 30 | 46 | 200 | IGST30045 |

Carbide shank arbor available

| MODEL | DIA | OAL | M | ORDER |

|---|---|---|---|---|

| 8M4100 | 8 | 100 | M4 | IGST1001 |

| 10M5100 | 10 | 100 | M5 | IGST1002 |

| 10M5150 | 10 | 150 | M5 | IGST1003 |

| 12M6100 | 12 | 100 | M6 | IGST1004 |

| 12M6150 | 12 | 150 | M6 | IGST1005 |

| 12M6200 | 12 | 200 | M8 | IGST1006 |

| 15M8100 | 15 | 100 | M8 | IGST1007 |

| 15M8150 | 15 | 150 | M8 | IGST1008 |

| 15M8200 | 15 | 200 | M8 | IGST1009 |

| 16M8150 | 16 | 150 | M8 | IGST1010 |

| 16M8200 | 16 | 200 | M8 | IGST1011 |

| 16M8250 | 16 | 250 | M8 | IGST1012 |

| 20M10150 | 20 | 150 | M10 | IGST1013 |

| 20M10200 | 20 | 200 | M10 | IGST1014 |

| 20M10250 | 20 | 250 | M10 | IGST1015 |

| 25M12150 | 25 | 150 | M12 | IGST1016 |

| 25M12200 | 25 | 200 | M12 | IGST1017 |

| 25M12250 | 25 | 250 | M12 | IGST1018 |

| 32M16150 | 32 | 150 | M16 | IGST1019 |

| 32M16200 | 32 | 200 | M16 | IGST1020 |

| 32M16250 | 32 | 250 | M16 | IGST1021 |

| 32M16300 | 32 | 300 | M16 | IGST1022 |

| 32M16350 | 32 | 350 | M16 | IGST1023 |

Material Application

a. Quenched and tempered structural steel: The carbon content of this type of steel is generally about 0.25% to 0.55%. For structural parts of a given cross-sectional size, when quenched and tempered along the cross-section during quenching and tempering (quenching and tempering), the mechanics.The performance is good. If the hardening is not penetrated and free ferrite appears in the microstructure, the toughness decreases. For steels with a tendency to temper brittleness, such as manganese steel, chromium steel, nickel-chromium steel, etc., they should be cooled quickly after tempering. The quenching critical diameter of this type of steel increases with the increase in grain size and alloying element content. For example, 40Cr and 35SiMn steel are about 30-40mm, and 40CrNiMo and 30CrNi2MoV steel is about 60-100mm, which is often used in manufacturing Structural parts such as shafts and connecting rods with large loads.cat40 end mill holder

b. Surface hardened structural steel: used to manufacture hard and wear-resistant surface parts and flexible parts, such as gears and shafts. In order to increase the toughness of the core of the part, the carbon content in the steel should be low, generally 0.12 to 0.25%, and there is also an appropriate amount of alloy elements to ensure proper hardenability. Nitrided steel also needs to add alloy elements (such as Al, Cr, Mo, etc.) that are easy to form nitrides. Carburized or carbonitrided steel, after carburizing or carbonitriding at 850~950℃, quenched and used under low-temperature tempering (about 200℃). The nitrided steel is directly treated by nitriding (480~580℃), and it is no longer quenched and tempered.