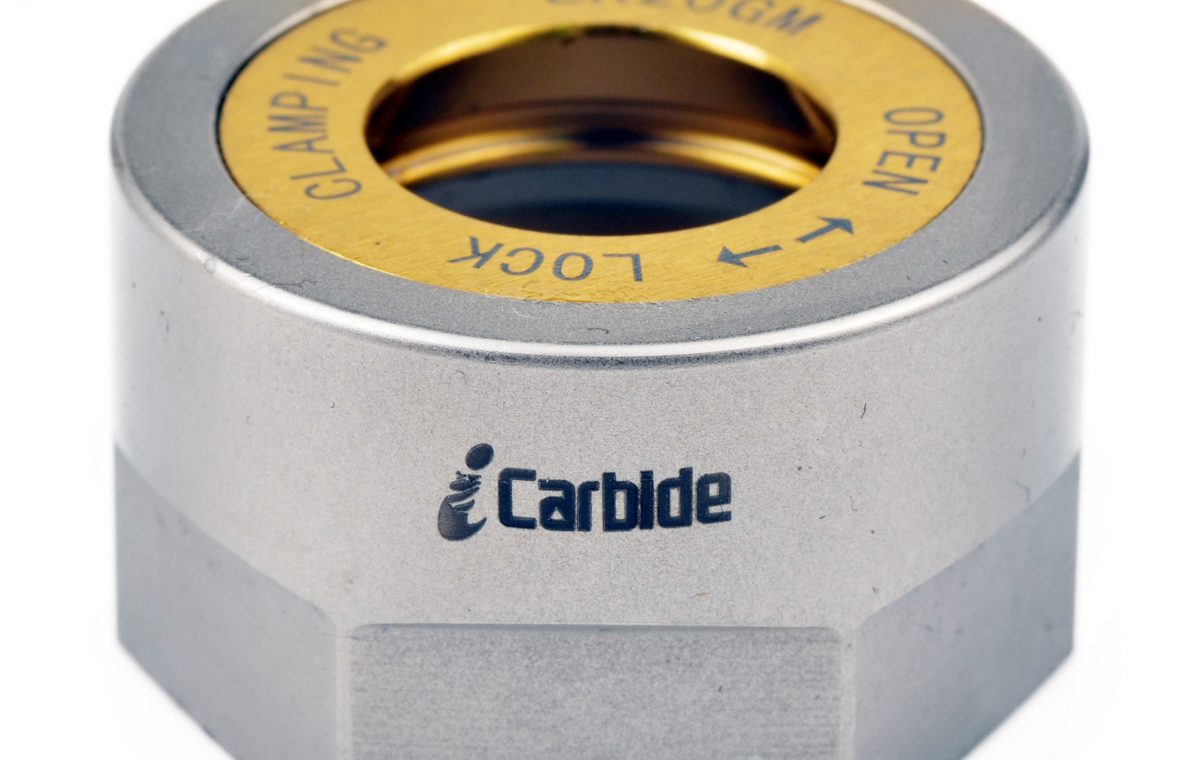

High-Performance Carbide Inserts

Focus on CNC blades and create an international brand! iCarbide Cutting Tools professional manufacturer.

The company has tiltable ball mills, spray granulation towers, CNC electric self-pressing machines, low-pressure vacuum sintering furnaces, peripheral grinders, CNC forming tool grinders, automatic passivation machines, CVD and PVD coating furnaces, high-speed milling machines, and electric discharge machines, Slow-moving wire cutting machine, linear detector, magnetic saturation meter, coercive force machine, metallographic microscope, etc. A cemented carbide CNC blade production line introduced from developed countries, with an annual output of more than 20 million pieces, and has passed ISO9001 international quality System Certification.

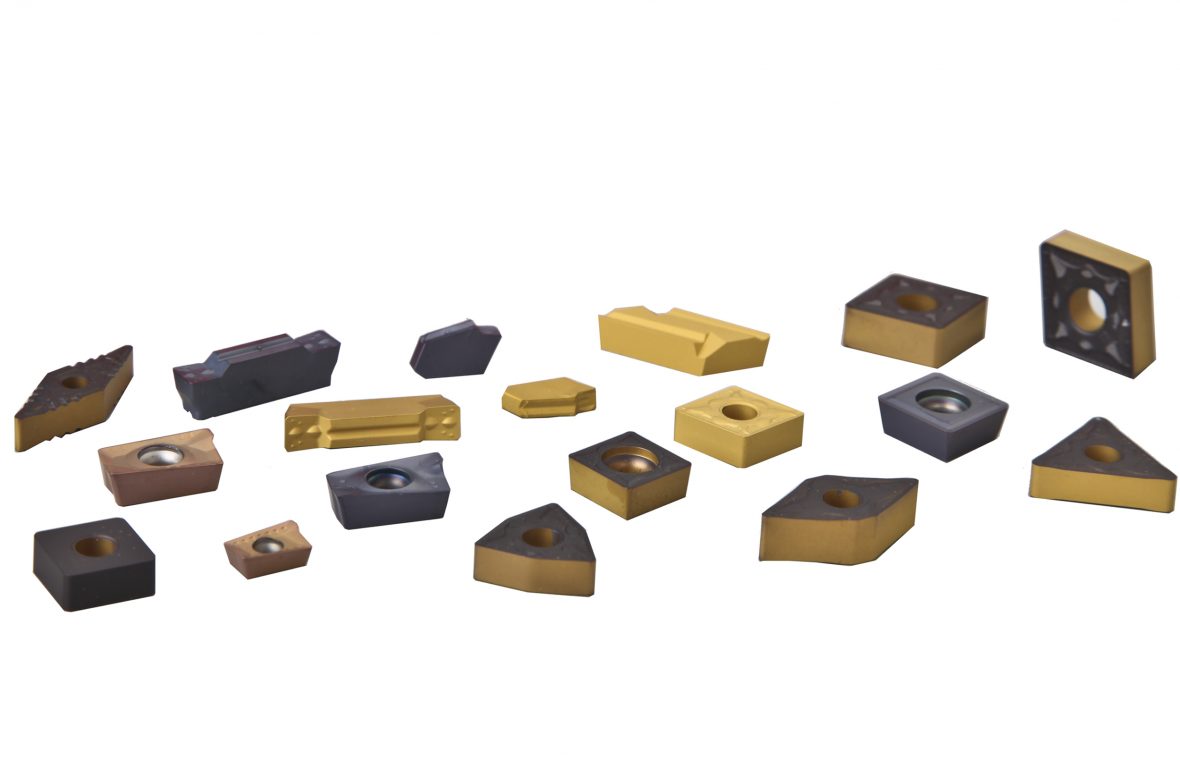

Our products have been exported to Europe, America, Southeast Asia, the Middle East, and other regions in batches. There are three products:

1. Aluminum, cast iron, stainless steel, various steel and other metal cutting special vehicles, milling, cutting grooves, drilling and milling, and other hard alloys and Metal ceramic thick film composite coating indexable blades and their cutting tools, as well as welding blades;

2. Carbide woodworking tools such as machine-clamped woodworking blades, woodworking drills, straight knives, hinge drills, and precision woodworking planers;

3. Knife pads, Diamond and CBN tool bases, mining buttons, plates, bars, drawing dies, stamping dies, and other hard alloy products; we can also customize various hard alloy products according to your drawings and samples.

Read More