Electromagnetic Induction Heating

The working principle of electromagnetic heating is that electronic circuits generate an alternating magnetic field. When a ferromagnetic metal object is placed within this magnetic field, the magnetic field lines cut through the surface of the metal, inducing alternating electric currents inside the metal (eddy currents). These eddy currents cause the metal atoms to move rapidly and irregularly, resulting in atomic collisions and friction, which generate heat energy.

As a result, the metal itself becomes the heat source, achieving direct heating of the workpiece.

Because the heat is generated directly inside the metal, electromagnetic induction heating offers extremely high thermal efficiency, with energy conversion efficiency reaching up to 95%. It is therefore a highly efficient direct-heating method. This principle is widely applied in induction furnaces, induction cookers, and industrial electromagnetic heating systems.

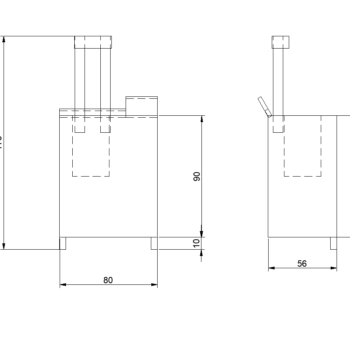

1. Shirnk fit machiner Heater

An electromagnetic heater is a device that converts electrical energy into thermal energy using the principle of electromagnetic induction.

The electromagnetic heating controller rectifies 220V, 50/60Hz AC power into DC, and then converts the DC power into high-frequency power (20–40 kHz) for heating applications.

Alternatively, 380V, 50/60Hz three-phase AC power can be rectified into DC and then converted into high-frequency, low-voltage, high-current power (10–30 kHz), which is commonly used for industrial heating processes.

2. Induction Heating Coil

When high-frequency current flows through the induction heating coil, it generates a rapidly changing alternating magnetic field.

When a ferromagnetic metal workpiece is placed within this field, the magnetic field lines cut through the metal surface, inducing alternating eddy currents inside the metal. These eddy currents cause rapid and irregular atomic motion within the metal, leading to collisions and friction that generate heat energy.

This process heats the workpiece by converting electrical energy into magnetic energy and then into thermal energy through induced eddy currents on the metal surface.

Compared with traditional resistance heating methods such as heating plates or electric heating wires, electromagnetic induction heating fundamentally solves the problem of low heating efficiency caused by heat transfer losses, resulting in significantly higher efficiency and faster heating.