M16 BT40 10MM x3.15″ SHRINK FIT TOOL HOLDER

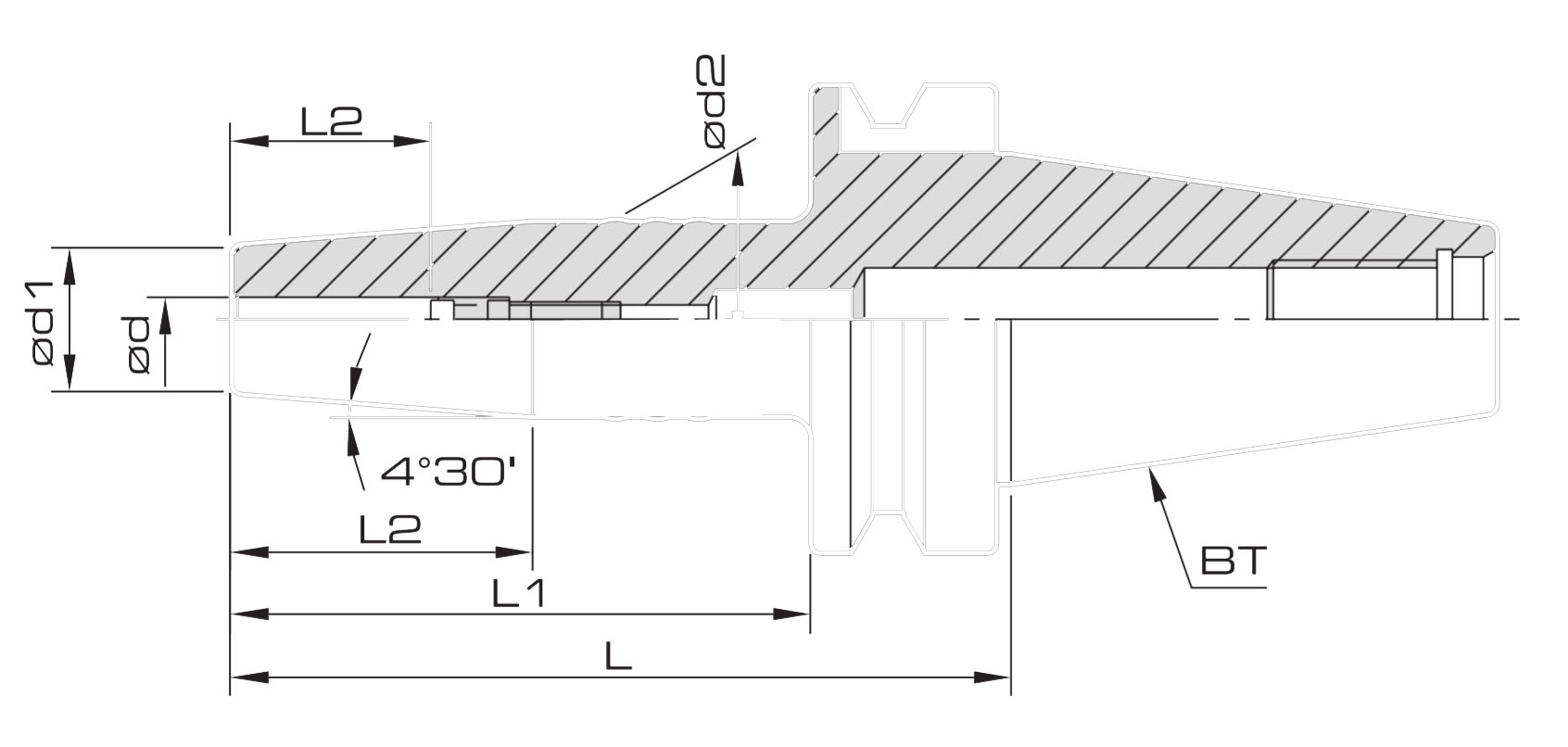

| MODEL | BT40 SF06 80 | RUN OUT (TIR) | 0.0001″ | NOSE DIAMETER D | 25MM |

| HOLDER TYPE | SHRINK FIT | BORE DIAMETER | 6MM | BORE DEPTH | 22MM |

| SHANK TYPE | BT40 | DRAWBAR THREAD | M16X2 | NOSE DIAMETER d | 22MM |

| BALANCE | G2.5 25000rpm | Gage Length | 3.15″ | COOLANT | NO |

Shrink fit tool holder for all BT40 spindle tool holder

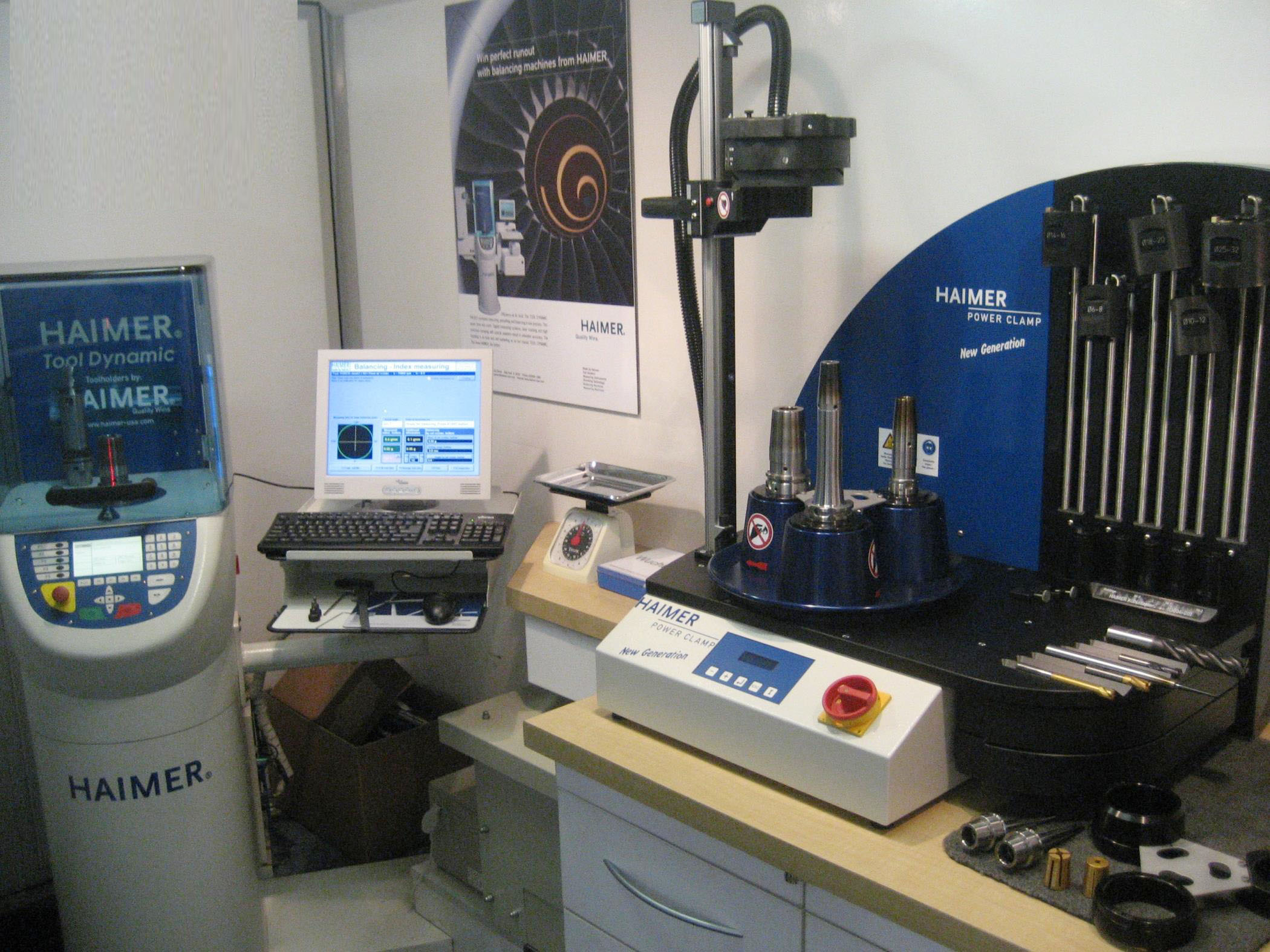

The quality reach HAIMER shrink fit holder

Advantages of shrink tool holders:

1. Fast loading and unloading of tools, using heat shrinking machine to heat, 13KW high power can complete the tool installation and clamp within 5 seconds, cooling only 30 seconds, the unique water cooling device can prevent the accuracy of the tool holder from deteriorating.

2. High precision and small runout. The tool installation part does not have components such as nuts and collets required by collet chucks, simple and effective, cold shrinkage clamping is strong and stable, tool deflection ≤3μ, reducing tool wear and ensuring high precision during high-speed machining.

heat holder socks heat holder gloves heat holder thermal socks heat holder socks walmart ,High precision run out saving your cost-effective haimer shrink fit

Quality Control

Material Application

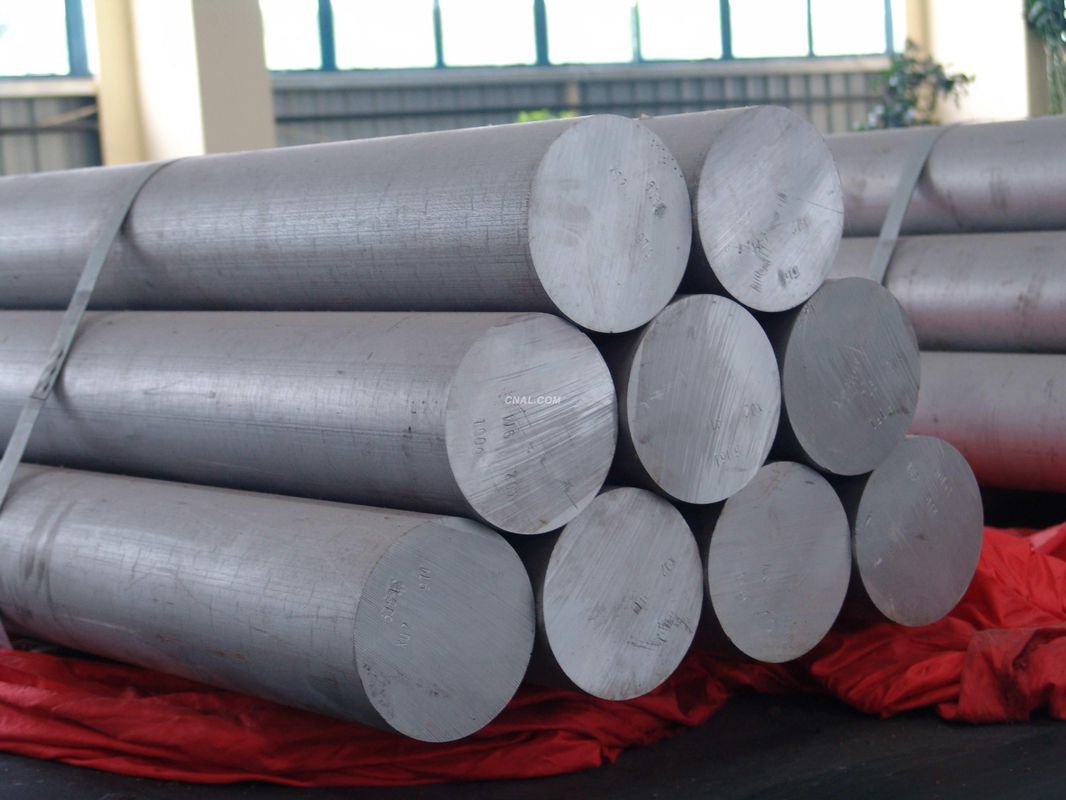

H13 steel is the most widely used and most distinctive hot work die steel. Its main characteristics are:

(1) It has high hardenability and high compensation;

(2) Excellent thermal crack resistance, water cooling can be added in the workplace;

(3) It has medium abrasion resistance, and can also use infiltration carbon or nitriding process to increase its surface hardness, but it should slightly reduce the thermal crack resistance;

(4) Due to its reduced carbon content, the secondary hardening ability during tempering is poor;

(5) It can resist softening at higher temperatures, but the hardness drops rapidly when the use temperature is higher than 540°C (1000°F) (that is, the working temperature is 540°C);