I. Characters & Features

Use:

For all DIN6499 standard tool holder in ER Collets

Finishing & Rough Cutting:

High precision run out saving your cost-effective

Precision:

High Precision Runout: TIR 0.003μm or 0.00015

Hardened:

Outside: HRC48 Inside: HRC32

Size includes:

ER40 ER32 ER25 ER20 ER16 ER11 and ER8

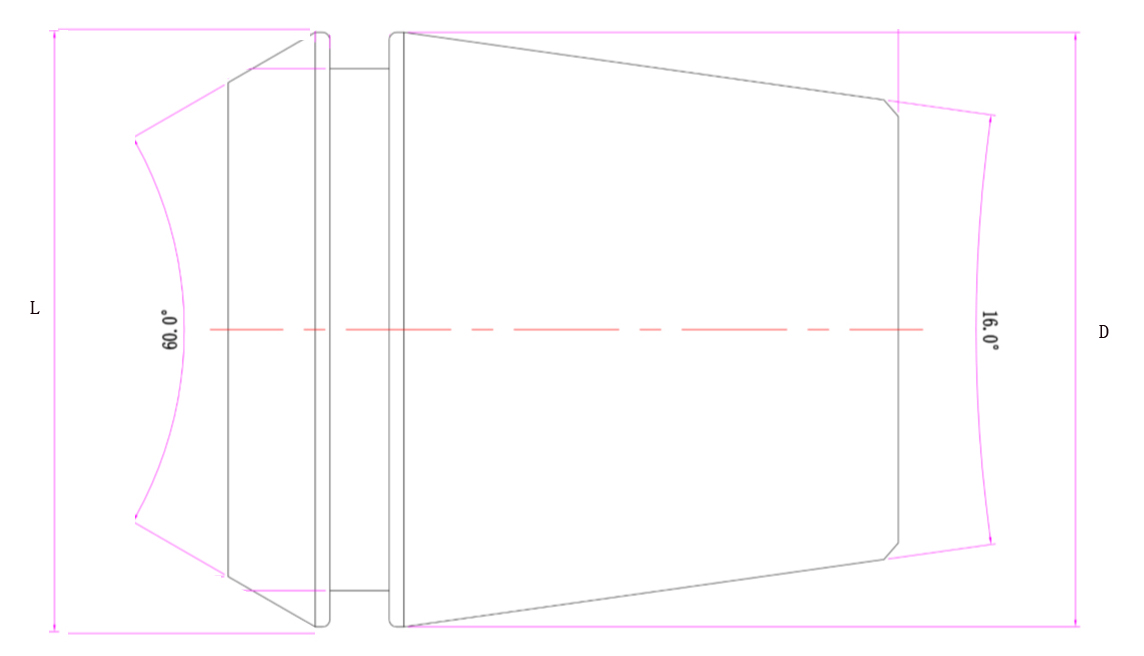

A. Drawings & Parameters Table

B. Select & buy our tool

| Order NO | D | L | Clamping Ф mm | Run Out | Slot | Price |

|---|---|---|---|---|---|---|

| ICER1101 | 11.5 | 18 | 1 | ≤ 10μm | 16 | 11.99 |

| ICER1102 | 11.5 | 18 | 1.5 | ≤ 10μm | 16 | 11.99 |

| ICER1103 | 11.5 | 18 | 2 | ≤ 10μm | 16 | 9.59 |

| ICER1104 | 11.5 | 18 | 2.5 | ≤ 5μm | 16 | 9.59 |

| ICER1105 | 11.5 | 18 | 3 | ≤ 5μm | 16 | 9.59 |

| ICER1106 | 11.5 | 18 | 3.5 | ≤ 5μm | 16 | 9.59 |

| ICER1107 | 11.5 | 18 | 4 | ≤ 5μm | 16 | 9.59 |

| ICER1108 | 11.5 | 18 | 4.5 | ≤ 5μm | 16 | 9.59 |

| ICER1109 | 11.5 | 18 | 5 | ≤ 5μm | 16 | 9.59 |

| ICER1110 | 11.5 | 18 | 5.5 | ≤ 5μm | 16 | 9.59 |

| ICER1111 | 11.5 | 18 | 6 | ≤ 5μm | 16 | 9.59 |

| ICER1112 | 11.5 | 18 | 6.5 | ≤ 5μm | 16 | 9.59 |

| ICER1113 | 11.5 | 18 | 7 | ≤ 5μm | 16 | 9.59 |

| ICER1601 | 17 | 27.5 | 1 | ≤ 10μm | 16 | 11.99 |

| ICER1602 | 17 | 27.5 | 2 | ≤ 5μm | 16 | 11.99 |

| ICER1603 | 17 | 27.5 | 3 | ≤ 5μm | 16 | 8.39 |

| ICER1604 | 17 | 27.5 | 4 | ≤ 5μm | 16 | 8.39 |

| ICER1605 | 17 | 27.5 | 5 | ≤ 5μm | 16 | 8.39 |

| ICER1606 | 17 | 27.5 | 6 | ≤ 5μm | 16 | 8.39 |

| ICER1607 | 17 | 27.5 | 7 | ≤ 5μm | 16 | 8.39 |

| ICER1608 | 17 | 27.5 | 8 | ≤ 5μm | 16 | 8.39 |

| ICER1609 | 17 | 27.5 | 9 | ≤ 5μm | 16 | 8.39 |

| ICER1610 | 17 | 27.5 | 10 | ≤ 5μm | 16 | 8.39 |

| ICER2001 | 21 | 31.5 | 1 | ≤ 10μm | 16 | 11.99 |

| ICER2002 | 21 | 31.5 | 2 | ≤ 10μm | 16 | 11.99 |

| ICER2003 | 21 | 31.5 | 3 | ≤ 5μm | 16 | 8.39 |

| ICER2004 | 21 | 31.5 | 4 | ≤ 5μm | 16 | 8.39 |

| ICER2005 | 21 | 31.5 | 5 | ≤ 5μm | 16 | 8.39 |

| ICER2006 | 21 | 31.5 | 6 | ≤ 5μm | 16 | 8.39 |

| ICER2007 | 21 | 31.5 | 7 | ≤ 5μm | 16 | 8.39 |

| ICER2008 | 21 | 31.5 | 8 | ≤ 5μm | 16 | 8.39 |

| ICER2009 | 21 | 31.5 | 9 | ≤ 5μm | 16 | 8.39 |

| ICER2010 | 21 | 31.5 | 10 | ≤ 5μm | 16 | 8.39 |

| ICER2011 | 21 | 31.5 | 11 | ≤ 5μm | 16 | 8.39 |

| ICER2012 | 21 | 31.5 | 12 | ≤ 5μm | 16 | 8.39 |

| ICER2013 | 21 | 31.5 | 13 | ≤ 5μm | 16 | 8.39 |

| ICER2501 | 26 | 34 | 1 | ≤ 5μm | 16 | 15.59 |

| ICER2502 | 26 | 34 | 2 | ≤ 5μm | 16 | 15.59 |

| ICER2503 | 26 | 34 | 3 | ≤ 5μm | 16 | 10.79 |

| ICER2504 | 26 | 34 | 4 | ≤ 5μm | 16 | 10.79 |

| ICER2505 | 26 | 34 | 5 | ≤ 5μm | 16 | 10.79 |

| ICER2506 | 26 | 34 | 6 | ≤ 5μm | 16 | 10.79 |

| ICER2507 | 26 | 34 | 7 | ≤ 5μm | 16 | 10.79 |

| ICER2508 | 26 | 34 | 8 | ≤ 5μm | 16 | 10.79 |

| ICER2509 | 26 | 34 | 9 | ≤ 5μm | 16 | 10.79 |

| ICER2510 | 26 | 34 | 10 | ≤ 5μm | 16 | 10.79 |

| ICER2511 | 26 | 34 | 11 | ≤ 5μm | 16 | 10.79 |

| ICER2512 | 26 | 34 | 12 | ≤ 5μm | 16 | 10.79 |

| ICER2513 | 26 | 34 | 13 | ≤ 5μm | 16 | 10.79 |

| ICER2514 | 26 | 34 | 14 | ≤ 5μm | 16 | 10.79 |

| ICER2515 | 26 | 34 | 15 | ≤ 5μm | 16 | 10.79 |

| ICER2516 | 26 | 34 | 16 | ≤ 5μm | 16 | 10.79 |

| ICER3201 | 33 | 40 | 2 | ≤ 5μm | 16 | 16.79 |

| ICER3202 | 33 | 40 | 3 | ≤ 5μm | 16 | 16.79 |

| ICER3203 | 33 | 40 | 4 | ≤ 5μm | 16 | 11.99 |

| ICER3204 | 33 | 40 | 5 | ≤ 5μm | 16 | 11.99 |

| ICER3205 | 33 | 40 | 6 | ≤ 5μm | 16 | 11.99 |

| ICER3206 | 33 | 40 | 7 | ≤ 5μm | 16 | 11.99 |

| ICER3207 | 33 | 40 | 8 | ≤ 5μm | 16 | 11.99 |

| ICER3208 | 33 | 40 | 9 | ≤ 5μm | 16 | 11.99 |

| ICER3209 | 33 | 40 | 10 | ≤ 5μm | 16 | 11.99 |

| ICER3210 | 33 | 40 | 11 | ≤ 5μm | 16 | 11.99 |

| ICER3211 | 33 | 40 | 12 | ≤ 5μm | 16 | 11.99 |

| ICER3212 | 33 | 40 | 13 | ≤ 5μm | 16 | 11.99 |

| ICER3213 | 33 | 40 | 14 | ≤ 5μm | 16 | 11.99 |

| ICER3214 | 33 | 40 | 15 | ≤ 5μm | 16 | 11.99 |

| ICER3215 | 33 | 40 | 16 | ≤ 5μm | 16 | 11.99 |

| ICER3216 | 33 | 40 | 17 | ≤ 5μm | 16 | 11.99 |

| ICER3217 | 33 | 40 | 18 | ≤ 5μm | 16 | 11.99 |

| ICER3218 | 33 | 40 | 19 | ≤ 5μm | 16 | 11.99 |

| ICER3219 | 33 | 40 | 20 | ≤ 5μm | 16 | 11.99 |

| ICER4001 | 41 | 46 | 3 | ≤ 5μm | 16 | 17.99 |

| ICER4002 | 41 | 46 | 4 | ≤ 5μm | 16 | 17.99 |

| ICER4003 | 41 | 46 | 5 | ≤ 5μm | 16 | 17.99 |

| ICER4004 | 41 | 46 | 6 | ≤ 5μm | 16 | 17.99 |

| ICER4005 | 41 | 46 | 7 | ≤ 5μm | 16 | 17.99 |

| ICER4006 | 41 | 46 | 8 | ≤ 5μm | 16 | 17.99 |

| ICER4007 | 41 | 46 | 9 | ≤ 5μm | 16 | 17.99 |

| ICER4008 | 41 | 46 | 10 | ≤ 5μm | 16 | 17.99 |

| ICER4009 | 41 | 46 | 11 | ≤ 5μm | 16 | 17.99 |

| ICER4010 | 41 | 46 | 12 | ≤ 5μm | 16 | 17.99 |

| ICER4011 | 41 | 46 | 13 | ≤ 5μm | 16 | 17.99 |

| ICER4012 | 41 | 46 | 14 | ≤ 5μm | 16 | 17.99 |

| ICER4013 | 41 | 46 | 15 | ≤ 5μm | 16 | 17.99 |

| ICER4014 | 41 | 46 | 16 | ≤ 5μm | 16 | 17.99 |

| ICER4015 | 41 | 46 | 17 | ≤ 5μm | 16 | 17.99 |

| ICER4016 | 41 | 46 | 18 | ≤ 5μm | 16 | 17.99 |

| ICER4017 | 41 | 46 | 19 | ≤ 5μm | 16 | 17.99 |

| ICER4018 | 41 | 46 | 20 | ≤ 5μm | 16 | 17.99 |

| ICER4019 | 41 | 46 | 21 | ≤ 5μm | 16 | 17.99 |

| ICER4020 | 41 | 46 | 22 | ≤ 5μm | 16 | 17.99 |

| ICER4021 | 41 | 46 | 23 | ≤ 5μm | 16 | 17.99 |

| ICER4022 | 41 | 46 | 24 | ≤ 5μm | 16 | 17.99 |

| ICER4023 | 41 | 46 | 25 | ≤ 5μm | 16 | 17.99 |

| ICER4024 | 41 | 46 | 26 | ≤ 5μm | 16 | 17.99 |

C. Quality Control

E. QA Processing

D. Material Application

Japanese JIS standard SUJ2 high carbon chromium bearing steel, corresponding to the national

standard GCr15, SUJ2 high carbon chromium bearing steel, can be fully hardened, the hardness

can reach HRC58-61, has the wear resistance of the bearing, also strengthens the rigidity,

workability Good, and can be directly processed and shaped, using mold times 2-3 times higher

than SKD-61 (HRC52) full hardware. During quenching and tempering, the size does not change much,

and fatigue resistance is quite good.

E. Send Inquiry to Us for free

We will, as always, send samples to the consulting clients to ensure high-quality performance and reasonable prices. We focus on CNC Cutting tools & Tool System etc, provide the best tool for clients of different types of operations.

Please no, hesitate to send an inquiry to us!